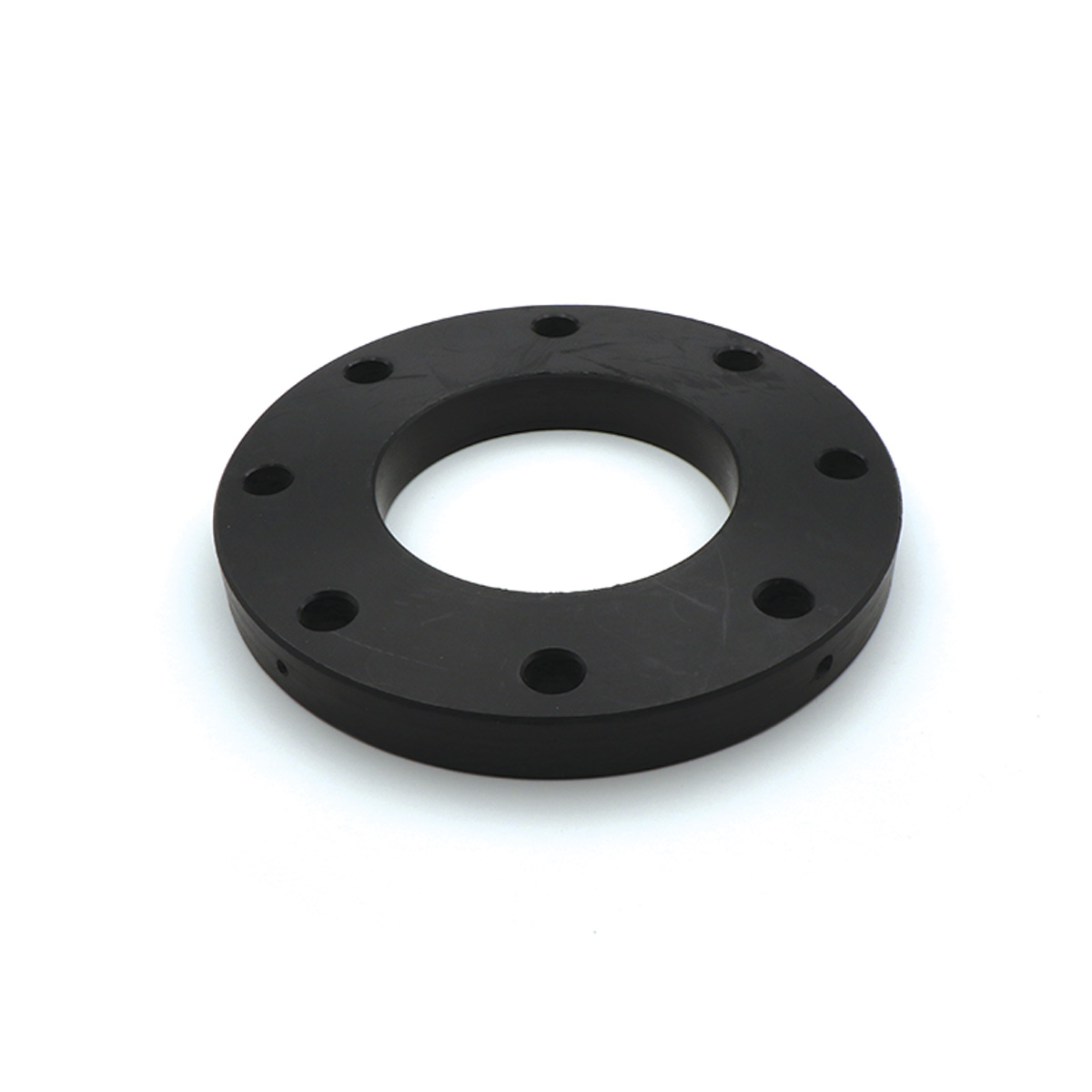

The polyethylene ring is a key component in the flanged connection of polyethylene pipes, and accurate selection of size, pressure rating (PN), and installation method directly affects the sealing, durability, and safety of the line. In this guide, we clarify technical concepts such as D, d3, d2, K, and T, explain the difference between PN10 and PN16, provide dimensional tables, and review professional selection and installation tips.

Definition of Marking and Terms for Polyethylene Ring

D: Overall outside diameter of the ring (mm)

d3: Overall inside diameter of the ring (mm)

d2: Diameter of the bolt holes on the ring (mm)

K: Pitch circle diameter (PCD), center-to-center distance of two opposite holes (mm)

T: Ring thickness (mm)

Number of bolts: Number of holes/bolts required to connect two flanges

Note: Correct selection of K and d2 ensures precise overlap with the matching flange and prevents stress irregularity and leakage.

Difference Between PN10 and PN16 Polyethylene Rings

Application: PN10 is typically used for low-pressure water and wastewater networks and lines with low water-hammer; PN16 is for higher-pressure lines or more severe transients.

Dimensions and strength: In many sizes, T and sometimes d2 and K are larger in PN16 to increase tensile capacity and tightening torque tolerance.

Compatibility: The ring must match the corresponding flange class, gasket type, and bolt class (e.g., class 8.8).

Dimensional Table of Polyethylene Ring PN10

Units: millimeter

| Nominal size | D | d3 | K | d2 | Number of bolts | T |

|---|---|---|---|---|---|---|

| 63 | 165 | 78 | 125 | 18 | 4 | 18 |

| 75 | 185 | 92 | 145 | 18 | 4 | 18 |

| 90 | 200 | 108 | 160 | 18 | 8 | 20 |

| 110 | 220 | 128 | 180 | 18 | 8 | 20 |

| 125 | 250 | 135 | 210 | 18 | 8 | 22 |

| 160 | 285 | 178 | 240 | 22 | 8 | 25 |

| 180 | 285 | 188 | 240 | 22 | 8 | 25 |

| 200 | 344 | 235 | 295 | 22 | 8 | 28 |

| 225 | 344 | 238 | 295 | 22 | 8 | 28 |

| 250 | 410 | 288 | 350 | 22 | 12 | 30 |

| 315 | 455 | 338 | 400 | 22 | 12 | 35 |

| 355 | 505 | 312 | 460 | 26 | 16 | 35 |

| 400 | 565 | 352 | 515 | 30 | 16 | 40 |

Dimensional Table of Polyethylene Ring PN16

Units: millimeter

| Nominal size | D | d3 | K | d2 | Number of bolts | T |

|---|---|---|---|---|---|---|

| 63 | 165 | 78 | 125 | 18 | 4 | 18 |

| 75 | 185 | 92 | 145 | 18 | 4 | 18 |

| 90 | 200 | 108 | 160 | 18 | 8 | 20 |

| 110 | 220 | 128 | 180 | 18 | 8 | 20 |

| 125 | 250 | 135 | 210 | 18 | 8 | 22 |

| 160 | 285 | 178 | 240 | 22 | 8 | 25 |

| 180 | 285 | 188 | 240 | 22 | 8 | 25 |

| 200 | 344 | 235 | 295 | 26 | 12 | 28 |

| 225 | 344 | 238 | 295 | 26 | 12 | 28 |

| 250 | 410 | 288 | 355 | 26 | 12 | 30 |

| 315 | 455 | 338 | 410 | 26 | 12 | 35 |

Material, Coating, and Common Standards

Common ring material: Carbon steel with suitable strength (as-is, epoxy-painted, or hot-dip galvanized for corrosion resistance).

Gasket: EPDM is typical for potable water; NBR for hydrocarbons; graphite or PTFE options for higher temperature/pressure.

Dimensional compatibility: Conformity with common flange standards and bolt-hole patterns is essential to maintain uniform load distribution.

Proper Installation Method for PE Ring and Flange

Surface preparation: Clean both pipe ends thoroughly; no chipping or out-of-roundness.

Placing the ring: Seat each ring on the pipe end; ensure d3 matches the pipe’s outside diameter.

Welding flange to pipe: Weld flanges per manufacturer’s instructions while maintaining coaxial alignment.

Gasket selection: Gasket ID must match the free bore of the flange/ring so its edge does not protrude into the flow.

Bolt and nut arrangement: Use the quantity and size listed in the table; threads must be clean and smooth.

Cross-pattern tightening: Tighten bolts in a star pattern in multiple passes with increasing torque to equalize gasket pressure.

Leak check: After initial sealing, gradually bring the system up to working pressure and check for leaks.

Professional Tips for Selecting a PE Ring

Design pressure: Choose between PN10 and PN16 based on maximum operating pressure and transients (water hammer).

K and d2 compatibility: Before purchase, match K and d2 with the existing flange drawing to avoid drill mismatch.

Coating quality: In corrosive environments (coastal/chemical), select protective coatings such as hot-dip galvanizing or heavy-duty epoxy.

Tightening torque: Follow the manufacturer’s torque tables for the bolt class; excessive torque can cut the gasket or warp the ring.

Periodic maintenance: After several pressure cycles, re-check bolt torque—especially on lines with significant temperature swings.

Applications of PE Rings and Flanges

Transmission and distribution lines for urban and rural water

Irrigation networks and wastewater transfer

Oil and gas lines (with suitable gasket and coating selection)

Chemical industries and fire-prone environments

Marine and coastal applications with high corrosion risk

Common Mistakes and Solutions

PN mismatch with actual pressure: Leads to early leakage; perform pressure and surge calculations before purchase.

Ignoring K: Causes skewed bolting and stress concentration; always match PCD to the flange drawing.

Inappropriate gasket: Material not compatible with the fluid/temperature disrupts sealing; align gasket material with service conditions.

Uneven tightening: Strictly follow cross and multi-stage tightening sequence.

«Tamam Baha», as a reputable supplier of PE rings and flanges in Iran, offers a wide range of PN10 and PN16 rings in various sizes. For English-speaking engineers and contractors across the region, the team emphasizes clear technical data, guidance on selecting K, d2, and T, and the provision of suitable gaskets/bolts to ensure fast installation, reliable sealing, and long-term line stability.