Brass valves have, since their inception, traversed a long path to reach their present standing in plumbing and interior design. The copper–zinc alloy, with copper content ranging from 58% up to about 72% depending on the application, creates a structure that combines high malleability with desirable mechanical strength, chemical resistance, and thermal conductivity. These very traits are why this class of valves is widely used in municipal hot- and cold-water lines, HVAC systems, and even high-end architectural projects. Below, we examine deeper details of manufacturing engineering, technical standards, benefits and challenges, maintenance strategies, and a comprehensive buying guide to provide a complete picture of why and how to choose brass valves.

Emergence and Historical Evolution of Brass Alloy in Water Supply

Archaeological evidence indicates that Roman craftsmen were the first to use brass in water pipes and household hardware. In the Middle Ages, European workshops dramatically improved the quality of this alloy by refining melting furnaces and inventing precise casting methods. With the Industrial Revolution and coke-fired furnaces in the 19th century, mass production of brass with controlled composition became possible—leading to standardized plumbing parts and valves. Today, modern factories use induction melting equipment, spectrographic analysis, and cold-forging lines to produce brass with tight chemical and dimensional tolerances, ensuring product durability and aesthetics under the toughest operating conditions.

Step-by-Step Production Process

- Selecting brass billets: Preparing the base alloy with specified percentages of copper, zinc, and minor amounts of tin or lead to improve machinability.

- Casting or forging: Depending on the valve type (rotary, piston, ball), hot forging or die-casting is performed; hot forging yields finer grain size and higher mechanical properties.

- Precision machining: Drilling, threading, and CNC turning to achieve smooth sealing surfaces and uniform dimensions.

- Surface finishing: High-gloss polishing, matte sandblasting, or nickel-chrome plating, and sometimes a clear protective lacquer to stabilize the alloy’s color.

- Assembly and leak testing: Using NBR or EPDM O-rings, silver soldering on joints, and hydrostatic pressure tests up to twice the rated pressure.

- Controlled packaging: Vacuum shrink with silica-gel protectors to prevent oxidation prior to final installation.

Technical Standards and Safety Requirements

| Standard Family | Reference Code | Controlled Domain | Distinguishing Note |

|---|---|---|---|

| ASTM B124 | C37700 | Chemical composition of forged alloy | Lead limit < 2.5% for drinking-water applications |

| EN 12165 | CW617N | Mechanical properties of forged parts | Mandatory tensile test and Brinell hardness |

| ISO 5208 | – | Tightness testing | Permitted leakage rate Class A (Zero Leakage) |

| NSF/ANSI 61 | – | Potable-water health | Limit on heavy-metal migration into water |

Complying with these standards in combination not only ensures build quality but also enables export to the stringent markets of Europe and North America.

Engineering and Design Features

Corrosion Resistance

The α-brass phase with higher copper concentration exhibits more stable behavior than the β phase in household chloridic environments. This minimizes periodic replacement and reduces total ownership cost.

Thermal Conductivity and Temperature Stability

With a thermal conductivity of about 110 W/m·K, brass quickly moderates the valve’s surface temperature, reducing the risk of user burns. Its melting point (920–960 °C) also ensures operational safety in settings such as steam boiler rooms.

Design Flexibility

The ability to achieve mirror polishing, brushed finishes, and even PVD coatings in rose-gold or matte black gives architects the freedom to use brass valves comfortably in neoclassical, minimal, or industrial styles.

Key Benefits

- Low friction factor along the flow path, reducing network pressure drop.

- Intrinsic antimicrobial properties of copper that help limit Legionella and Pseudomonas growth in building plumbing.

- Fully recyclable; ~90% of replaced parts enter the recycling loop, delivering environmental savings.

- Color stability under visible and UV light compared to pure chrome, which tends to haze over time.

Engineering Challenges and Solutions

- Initial cost: Using die-less cold forging reduces energy consumption and lowers final cost by up to 15% compared to conventional casting.

- Zinc-leaching (dezincification): Adding a trace amount of tin and maintaining water-network pH in the 6.5–8.5 range are effective routes to mitigate this selective corrosion.

- Relatively high weight: Designing hollow bodies preserves strength while cutting weight by up to 25%, easing ceiling or wall installation.

Comprehensive Comparison with Steel and Cast-Iron Valves

| Performance Parameter | Brass | Cast Iron | Stainless Steel 304 |

|---|---|---|---|

| Density (g/cm³) | ~8.4 | ~7.1 | 8.0 |

| Absolute Roughness (µm) | 1.5 | 12 | 0.9 |

| Chloride Resistance | Very good | Moderate | Excellent |

| On-site Repairability | Easy | Difficult | Moderate |

| Average Service Life (years) | 25–30 | 15–20 | 30–35 |

| Upfront Cost (relative) | 1.3× | 1× | 1.8× |

Relying on this table enables more precise techno-economic decisions for residential, office, or industrial projects.

Preventive Maintenance Guidelines

- Weekly cleaning with a 5% white-vinegar solution in lukewarm water to remove carbonate deposits without harming the plating.

- Annual application of microcrystalline wax to prevent green patina in humid coastal regions.

- Semiannual inspection of cartridges and O-rings; timely replacement of NBR washers before heat-induced hardening prevents sudden leaks at joints.

- Use an 80-mesh screen filter at the building inlet to remove suspended particles and extend the life of PTFE sealing seats.

Specialized Buying Guide

- Certificate analysis: Choose products that, in addition to national standard marks, hold NSF 61 approval and DIN 3230 pressure tests.

- Project needs: For a 90 °C hydronic line, opt for a valve with double nickel-chrome plating, which has higher oxidation resistance at elevated temperatures.

- Cartridge quality: A Class-S ceramic cartridge with a 90-degree rotation ensures 500,000-cycle wear resistance.

- Ownership cost forecasting: Review initial price, installation costs, service interval, and alloy recycling rate to calculate TCO (Total Cost of Ownership).

Specialized Applications in Various Industries

- Food & beverage: Lead-free grades (e.g., CW617N-LS) are used in dairy and juice filling lines.

- Fire-fighting systems: Brass bodies are preferred in angled Dry Riser valves due to resistance to corrosion from brackish water stored in underground tanks.

- Shipbuilding: The presence of zinc enhances anti-fouling on sea-water intake hatches.

- Hospitals: Copper’s antimicrobial traits help curb MRSA in operating-room wash units.

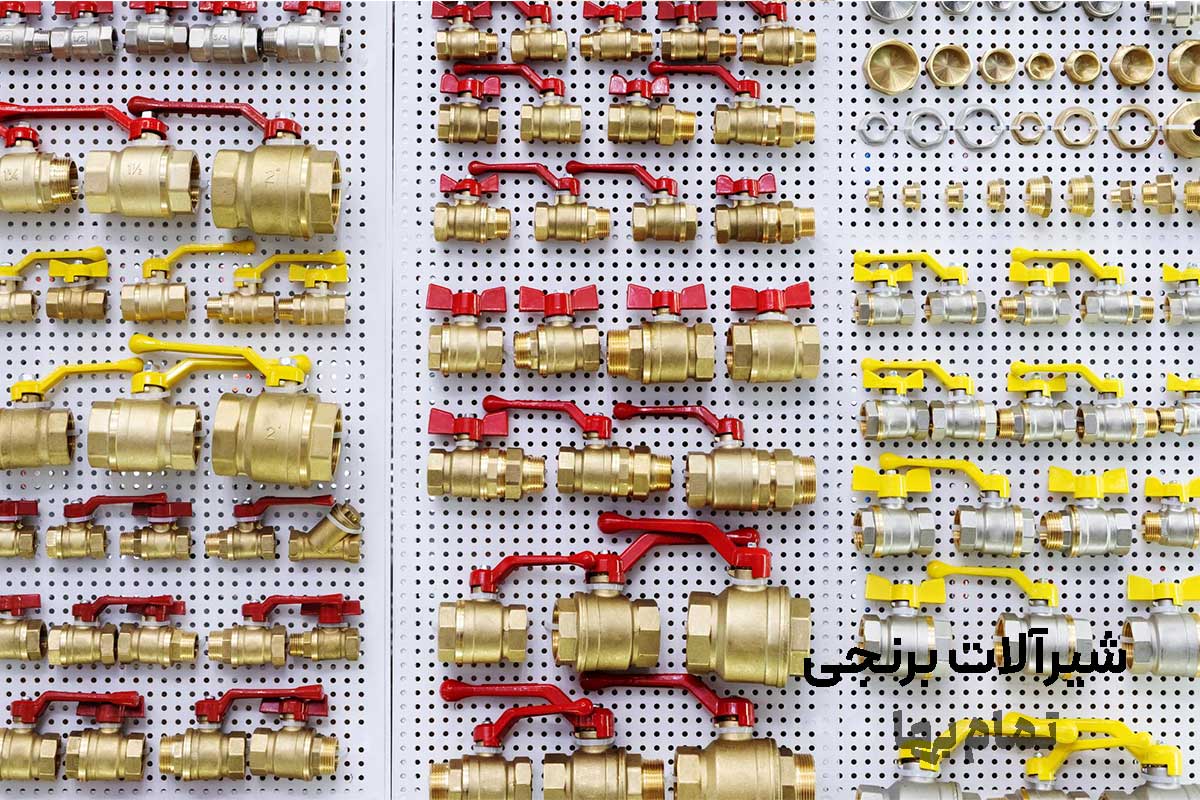

Tamam Baha Online Store, with a proven track record in supplying plumbing equipment, offers a complete basket of brass valves from reputable domestic and imported brands. Alongside pre-purchase technical consultation, customers can choose from a wide range of alloy grades, finishes, and thread sizes, and thanks to an efficient distribution network, orders are delivered promptly—an advantage that adds clear value for contractors and facility managers working on residential and service projects.