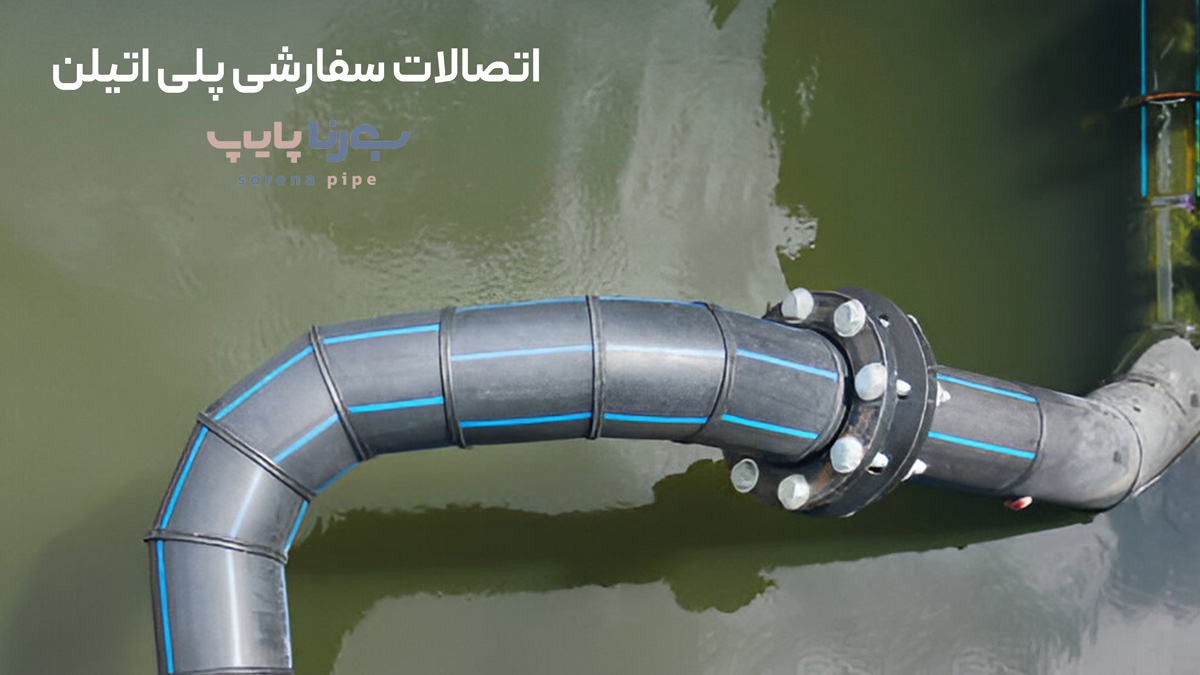

Custom polyethylene fittings encompass a wide spectrum of engineering-driven parts designed and manufactured to meet special needs in pipeline systems—requirements that go beyond what off-the-shelf injection-molded standard fittings provide. This group of fittings is also known as “hand-made PE fittings,” “mitered fittings,” or “machined PE fittings,” and their essence is the butt-fusion of cut segments from HDPE pipes in PE100 or PE80 grades. Below, with a comprehensive approach aligned with up-to-date SEO algorithms, all technical, practical, and economic aspects of these fittings are explained to serve as a complete reference for engineers and contractors.

Reasons Custom Fittings Outperform Standard Options

- Unbounded design envelope: Any diameter, angle, wall thickness, or fitting configuration can be produced given an engineering file—or even a simple sketch. Thus, pipeline routes with 27°, 33°, or any non-conventional bend angles are handled with ease.

- Cost optimization at large sizes: For diameters above ~400 mm, the cost of injection molds is so high that custom fabrication is not only cheaper but often the only viable option.

- Material continuity with the main line: Using the same pipe intended for the network (typically PE100–RC) ensures uniform mechanical properties, elastic modulus, and slow crack growth rate.

- Corrosion and chemical resistance: HDPE is inherently stable against brine, dilute mineral acids, bases, and a wide range of chemical solutions—an advantage that would otherwise require expensive anti-corrosion coatings on metals.

- Low weight and easy handling/installation: With density around 0.95 g/cm³, even sizes above 1 m can be moved with lighter cranes, minimizing lining or hook-up costs.

Engineering, Manufacturing, and Quality Control Steps

Project Data Collection

The line isometric drawing (ISO), design pressure, fluid temperature, outside diameter (OD), and pressure class (PN) form the design basis.

3D Design and Stress Simulation

Software such as CAESAR II or SolidWorks Simulation is used to evaluate weld-zone stresses and stress concentration where the cross-section changes.

Cutting and Machining

Precision cutting is performed by CNC or a miter band saw; angle accuracy of ±0.25° is standard to prevent a joint-face gap exceeding 0.5 mm.

Butt-Fusion Welding

- Heater temperature: 210–225 °C

- Initial (bead-up) pressure: 0.15–0.30 MPa depending on diameter and SDR

- Cooling time: 10–12 s per millimeter of wall thickness

- Qualification: Welder must hold Polymer Welding Union Level-2 certification.

Non-Destructive and Destructive Tests

- Visual inspection to ensure uniform external bead

- Ultrasonic or X-ray testing for critical oil & gas projects

- Hydrostatic test at 1.5× working pressure for 1 hour

Issuing the Quality Certificate (QC Certificate)

Includes raw-material reports, welding parameters, and test results, delivered with the part to the client.

Table 1 – Technical & Economic Comparison of Two Connection Approaches in Piping Projects

| Indicator | Injection-Molded Fittings | Custom Fittings |

|---|---|---|

| Typical max diameter | Up to 315 mm (locally 500) | Up to 1200 mm and above |

| Available angles | 45° and 90° | 5° to 90° as required |

| Up-front tooling | High (metal mold) | Low (shared fusion machine) |

| Production rate (pcs/h) | Very high | Limited to a few per day |

| Unit weight at large sizes | Heavy | Lighter (optimized wall) |

| Weld traceability | Not available | Available (data logger) |

Full Range of Custom Fitting Types

- Engineering elbows from 8° to 90°, with reinforced heel thickness for pressures above PN25.

- Combined tees and crosses with offset inlets/outlets and multi-diameter branches—often used in chemical-injection manifolds or compact refinery piping.

- Concentric and eccentric reducers for velocity control and cavitation avoidance; in gravity sewer lines, eccentric type is the standard option.

- Multi-port manifolds (headers) up to 1000 mm main diameter with 63–225 mm branches, suitable for high-flow drip-irrigation systems.

- Specialized anti-wear fittings with internal layers of UHMW-PE composite or polymer-ceramic to boost abrasion resistance for mineral slurries.

Key Applications Across Industries

Municipal Water & Wastewater

Custom fittings enable precise route rotations in dense street grids and, by eliminating extra flanges, can reduce total cost by up to 12%.

Oil & Gas Pipelines

In corrosive environments such as sour-gas fields or wet-crude lines contaminated with H₂S, HDPE has become the first choice for short spools. Custom elbows made from PE100-RC help ensure the pipeline’s projected 50-year service life.

Chemical Treatment Plants

In contact with solutions like 50% NaOH or 30% HCl, metallic fittings require costly linings or epoxy coatings, whereas mitered PE fittings endure without additional coatings.

Agriculture & Smart Irrigation

Custom manifolds with 8–12 outlets significantly cut installation time, and due to low weight, simplify installation on sloped fields.

Common Quality-Control Tests

| Test | Reference Standard | Acceptance Criterion | Execution Timeframe |

|---|---|---|---|

| Hydrostatic 1.5×PN | ISO 1167 | Pressure drop ≤5% over 60 min | Post-fabrication |

| Shear-tensile of weld | DVS 2203-2 | Yield stress ≥90% of base material | Every 200 m of weld |

| Phased-array UT | ISO 19232 | No voids >1 mm | Critical lines |

| Visual bead review | ISO 21307 | Uniform bead height, no notches | All fittings |

Key Notes for Installation, Operation, and Maintenance

- Adequate mechanical support: Bed the fitting on graded sand Class B (particle size <10 mm) to avoid local stress points.

- Thermal-stress management: In regions with high temperature swings, use free expansion loops or flexible HDPE-RTP fittings.

- Periodic inspection: Watch for visible deformation, corrosion of metal clamps, or weld-seam leakage—early signs of failure; prompt remedy prevents slow crack growth (SCG).

- Metal transitions: When unavoidable, use aluminum-bronze or stainless-steel flanges with PE-coated long-neck design to eliminate galvanic effects.

Cost Estimation and Scheduling

The finished cost of custom fittings depends on raw-material weight, number of welds, and machining time. For a 630 × SDR17 elbow at 60°, material accounts for ~70% of total cost, and typical fabrication time is 3–5 working days. In EPC projects on the critical path, ordering at least two weeks before installation minimizes delay risk.

Tamam Baha’s Role in Supplying Custom Fittings

Tamam Baha maintains a comprehensive inventory of PE100 pipes and a CNC automatic fusion workshop, enabling the design, fabrication, and delivery of custom PE fittings in accordance with ISO 4427. Alongside sourcing from other market brands as a leading distributor, we provide technical consulting, shop drawings, and on-site installation support for projects across the Middle East and Europe. For pricing and delivery, share the required diameter, angle, and PN class with our specialists to receive a pro-forma invoice and technical datasheet within 24 hours.